Introduction

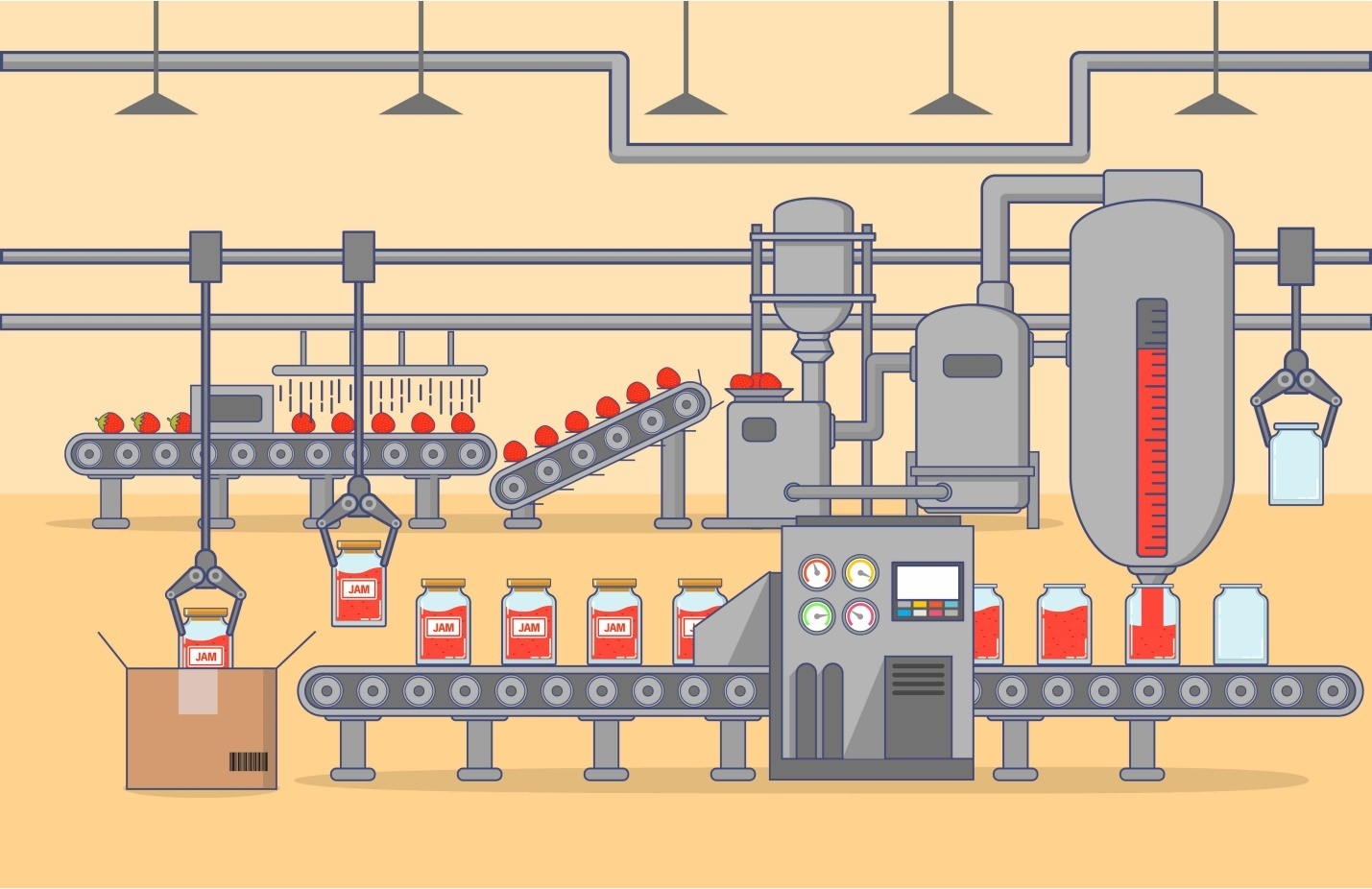

The number of different food products and the operations and steps involved in their production are indeed very great. Further, each manufacturer introduces departures in methods and equipment from the traditional technology for that product, and pro-cesses are in a continual state of evolution. The food scientist would soon experience great frustration if there were not unifying principles and a systematic approach to the study of these operations. The processes used by the food industry can be divided into common operations, called unit operations. Examples of unit operations common to many food products include cleaning, coating, concentrating, controlling, disintegrating, drying, evaporat-ing, fermentation, forming, heating/cooling (heat exchange), materials handling, mix-ing, packaging, pumping, separating, and others. These operations are listed alphabeti-cally, not in the order of their natural sequence or importance. Most unit operations are utilized in the making of a variety of food products. Heat exchanging, or heating, for example, is used in the manufacture of liquid and dry food products, in such diverse operations as pasteurizing milk, sterilizing foods in cans, roasting peanuts, and baking bread. Unit operations may include numerous different activities. The unit operation of mixing, for example, includes agitating, beating, blending, diffusing, dispersing, emul-sifying, homogenizing, kneading, stirring, whipping, and working. We may want to mix to beat in air, as in making egg white foam, or to blend dry ingredients, as in preparing a ton of dry cake mix; or we may wish to mix to emulsify, as in the case of mayonnaise, or to homogenize to prevent fat separation in milk. We may wish to mix and develop a bread dough, which requires stretching and folding, referred to as kneading. One of the key elements to food processing is the proper selection and combination of unit operations into more complex integrated processing systems. These operations and processes consume great quantities of energy.

Rationale

Lab performances, attendances, product preparation and exhibition, Reporting note book, Viva Voce and Final exam etc. are the main operational base to evaluate students learning feedback.

Objectives

To provide students with an understanding of the principles, technology and application of unit operations required and used in processing of food products. Different equipment like solid food, liquid food and necessary food stuffs based modern procedures are trained in these lab class.

- Teacher: Tajnuba Sharmin