Section outline

-

-

Class Schedule :

08:30-10:00

10:00-11:30

11:30-01:00

01:00-02:30

02:30-04:00

04:00-05:30

SATURDAY

SUNDAY

A3

MONDAY

A3

TUESDAY

WEDNESDAY

Counseling Hour :

Saturday : 10.00 am -01.00 pm

Tuesday : 10.00 am -11.30 am & 01.00 pm-2.30 pm.

Wednesday : 11.30 am -02.30 pm

-

-

Welcome Note

Dear Students,

Assalamu Alaikum and a very warm welcome to all of you.

This is Dr. Mainul Morshed, and I am here to conduct your new course Textile Wet Process-II and share and learn something new about the world of Wet Processing. So, let's gather knowledge with you all together. Feel free to approach me any kind of problem.

This course aims to provide students with an in-depth knowledge of the principles of textile preparatory processes and develop the students’ understanding on the important concept and technology of textile coloration.

Thank you very much.

Regards,

Course Teacher

Dr. Mainul Morshed

Assistant Professor

Department of Textile Engineering

Faculty of Engineering

Daffodil International UniversityCell : +8801406238336

Email : mainul.te@diu.edu.bdGeneral Course Description :

Course Title: Textile Wet Process- II

Course Code: TE 313

Credit Hours: 3 (Theory, 3 contact hours per week)

Prerequisite: TE-209 (Textile Wet Process-I)

Course Level: Level 3 Term 1

Course Objectives :

After the completion of this course, students will be able to-

1. Learn in-details about dyeing process of textiles with reactive, sulphur, azoic and disperse dyes by using discontinuous and continuous methods.

2. Know about printing process of woven and knit fabrics with reactive, sulphur, azoic and disperse dyes by using different methods, including block, screen and roller printing methods.

3. Attain knowledge about important chemical and mechanical finishes, such as textile mercerization, resin finishing, water repellent finishing and shearing process.

Course Content:

1. Technology of Dyeing

a. Reactive Dyes

b. Sulphur Dyes.

c. Disperse Dyes.

d. Azoic Dyes.

2. Technology of Printing

a. Introduction of Textile Printing, Functions and Types of textile thickener.

b. Methods and Styles of textile printing.

c. Block Printing, Screen Printing, Roller Printing.

d. Printing Faults.

e. Direct, Resist, Discharge, Burnout, Flock styles.

3. Technology of Finishing

a. Introduction to Textile Finishing

b. Mercerization Process

c. Shearing Process

d. Resin Finish

e. Water Repellent & Water Proof Finish

-

- Fundamentals and Practices in Colouration of Textiles by J.N Chakrabarti

- Technology of Bleaching and Mercerizing by Dr. V.A Shenai (Vol-III)*

- Dyeing and Chemical Technology of Textile fibres by E.R Trotman*

- Textile Coloration & Finishing by Warren S. Perking

- Textile Printing by W. Miles

- Basic Principle of Textile coloration by Arthur D. Broadbent

-

-

-

Assignment Title: Dyes and Their PropertiesRegulations:# The Assignment should be submitted hard copy first on or before 19 February, 2024.# For late submission there will be negative marking.# Assignment can be submitted in both printed or hand written format.# There is no limit of pages (but should not provide a thesis)# It Should be submitted by each and every single student by him/herself.# Any kinds of copy from other classmate's assignment would cause negative marking.# Every single student must submit the soft copy (.pdf version) of his/her assignment on or before 15/03/2024 on BLC. only soft copy submission will not be considered.# Late submission on BLC will also cause negative marking.# For online soft copy submission, students are must follow the criteria:File name should be ( Student ID + Student Name)

-

-

-

Presentation Date:Sec A3: 18/02/2024Regulations:# Each group will select there own topic.# Presentation will conduct group wise.# Total number of groups should be 7 for each section.# Each group should contain minimum of 7 persons.# Each group will get 10 minutes to finish there presentation.# There will be no second option for the presentation.# All male students must present themselves in formal dress up; for female students no dress code is applicable.# Every single group must submit the soft copy (.ppt version) of his/her assignment on or before 15/03/2024 on BLC.# Late submission on BLC will cause negative marking.# For online soft copy submission, students are must follow the criteria:File name should be (Section + Presentation topic)

Presentation Date:Sec A3: 18/02/2024Regulations:# Each group will select there own topic.# Presentation will conduct group wise.# Total number of groups should be 7 for each section.# Each group should contain minimum of 7 persons.# Each group will get 10 minutes to finish there presentation.# There will be no second option for the presentation.# All male students must present themselves in formal dress up; for female students no dress code is applicable.# Every single group must submit the soft copy (.ppt version) of his/her assignment on or before 15/03/2024 on BLC.# Late submission on BLC will cause negative marking.# For online soft copy submission, students are must follow the criteria:File name should be (Section + Presentation topic) -

-

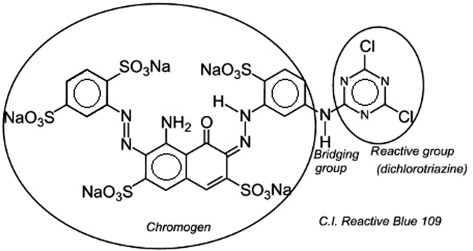

Chapter Objectives :

- To teach the students about the concepts and fundamentals of Textile dyeing.

- They also learn about reactive dyes and its characteristics, Reasons of popularity of reactive dyes, General structure of reactive dyes.

- Learn about the applying procedure of reactive dyes.

Chapter Outcomes :

After completing this chapter Students can,

- Learn about dyeing process of textiles with reactive.

- Know about the characteristics and general structure of reactive dyes.

- Know about its popularity.

- Know the dyeing mechanism with reactive dyes.

- Know about hydrolysis and stripping process of reactive dyes.

-

-

According to our knowledge on dyes, we came to know about the specific properties or the criteria to identify a chemical whether it is dye or not.

please have some discussions about the key criteria for a chemical to be a dye.

-

Fiber-reactive dyes form strong covalent bonds with cellulosic fibers, which result in good wash fastness. Reactive dyes are subject to hydrolysis, which is the chemical reaction of the dye with the water. Hydrolysis must be controlled for dye optimization. A wide range of reactive dye chemistries is available, resulting in a range of performance attributes. Dyeing Basics Dye Color Perception Basic Dyeing Principles Fiber Reactive Dyes Direct Dyes Vat Dyes Sulfur Dyes Pigments

-

Chapter Objectives :

- To teach the students about the concepts and fundamentals of Textile dyeing.

- They also learn about sulphur dyes and its characteristics.

- Learn about the chemistry of sulphur dyeing.

- Learn about the application of sulphur dyes in textile material.

Chapter Outcomes :

After completing this Chapter Students can,

- Learn about dyeing process of textiles with sulphur.

- Know about the basic difference between sulphur dyes and reactive dyes.

- Know the dyeing mechanism with Sulphur dyes.

- Know about stripping process of Sulphur dyes.

- Know about its popularity for producing black shades.

-

The first class test of Wet Process 2 course will held on the following dates on the respective class hours.

please check and take preparation according to the class sections.

CLass Test Schedule:

Section A3: 04/02/24

Rules and Regulations

Marks: 15

Duration of Class Test: 30 minutes

1st CT Syllabus

> definition of Dye and fastness> Dye and Chemical Calculations> Wet process flow chart> Trichromatic Combinations> Reactive Dyes and its properties> Classification of reactive dyes. -

The 2nd class test of Wet Process 2 course will held on the following dates on the respective class hours.

please check and take preparation according to the class sections.

CLass Test Schedule:

Section A3: 18/02/24

Rules and Regulations

Marks: 15

Duration of Class Test: 30 minutes

2nd CT Syllabus

> Dye and Chemical Calculations> Wet process flow chart> Trichromatic Combinations> Mechanism of Reactive Dyes> Reactive dye Structures> Functionality of Reactive Dyes -

Syllabus for Midterm Exam :

- Reactive dyes and its application (Definition, Features, Structures, Classification, Mechanism, Popularity, Details of dyeing process, Assistants, Hydrolysis & Stripping)

- Sulphur dyes and its application (Definition, Features, Structures, Mechanism/Chemistry, Details of dyeing process, Defects, Stripping, Applications, Popularity & Comparison)

- Introduction to Textile Printing (Definition, Methods & Styles name, Textile Thickener)

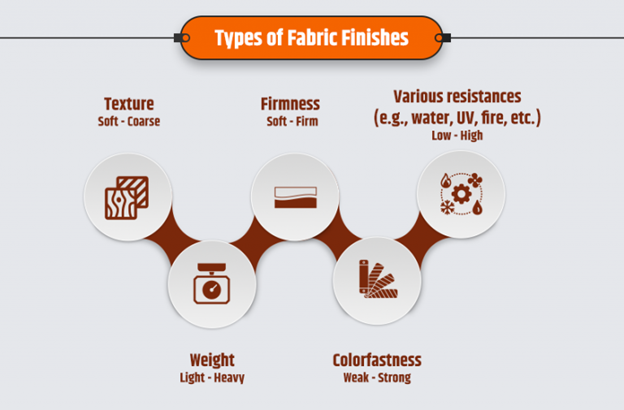

- Introduction to Textile Finishing (Definition, Classification, Objects & Factors)

Instructions for Midterm Exam :

Midterm Exam Assessment Plan

There will be

Short Question & Broad Question : Marks : 25Total = 25

Time : 1.5 hours

Midterm Exam Preparation

- Discuss with each other and find the problems regarding upcoming Midterm Examination

- If you have any problems that you can not solve, then inform me and we will discuss it in the classroom and here in the Chatbox

-

Chapter Objectives :

- To teach the students about the Disperse dyes and its characteristics.

- Learn about the dyeing mechanism of synthetic fibres with disperse dyes.

- Learn about the application procedure of disperse dyes.

Chapter Outcomes :

After completing this Chapter Students can,

- Learn about the characteristics of disperse dyes.

- Know how can it entrapped with the fibres.

- Know about Carrier, HTHP and Thermosol mrthod dyeing.

- Know about the classifications of disperse dyes.

-

Chapter Objectives :

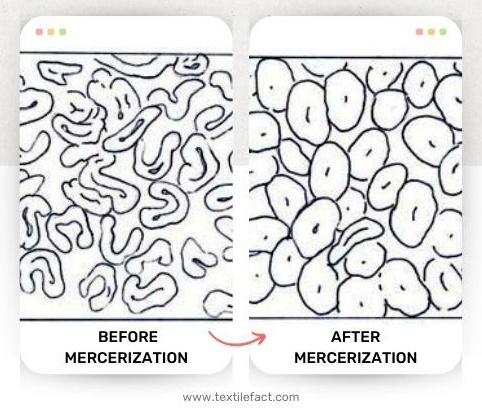

- Learn about the mercerization process.

- To teach them about shearing process.

- To teach them about resin finish.

Chapter Outcomes :

After completing this Chapter Students can,

- Learn about different finishing technology.

- Know about mercerization process.

- Know about shearing process.

- Know about resin finishing process.

-

This video is all about mercerization process of cotton fabric. Caustic soda mercerization of cotton is carried out for improvement of luster and dye uptake of cotton fabric that's why it is important process in textile industry. In this video you will learn how mercerization process changes physio-chemical properties of cotton. This change lead cotton fabric to bright luster appearance, good dye absorbency, fabric strength as compared to un mercerized cotton fabric.

-

Chapter Objectives :

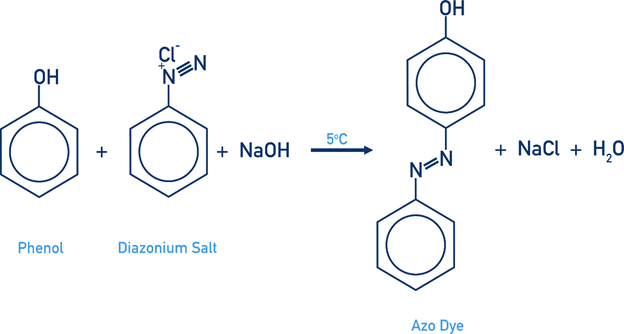

- To teach the students about the Azoic Colors and its characteristics.

- Learn about the chemistry of Azoic Color.

- Learn about the application procedure of Azoic Color.

Chapter Outcomes :

After completing this Chapter Students can,

- Learn about the different names of azoic color

- Know the chemistry of azoic color and its properties.

- Know about naphtholation, diazotization and coupling reaction.

- Know about the stripping process of azoic color.

-

Chapter Objectives :

- To teach the students about the fundamental of printing technology

- Learn about the printing mechanism.

- Learn about the printing method and styles.

- Also learn about thickener.

Chapter Outcomes :

After completing this Chapter Students can,

- Introduce with printing technology.

- Learn about the name of different styles and methods of printing.

- Know how will printing can be done on textile materials.

- Know about the thickener and print paste.

-

Chapter Objectives :

- To teach the students about the fundamental of finishing technology

- Learn about the objects of Textile finishing

- To teach them about factors of Textile finishing

- To teach them about classification of Textile finishing

Chapter Outcomes :

After completing this Chapter Students can,

- Introduce with finishing technology.

- Know how and why need to do finish in a textile material.

- Know about classifications of Textile finishing.

-

Syllabus for Final Exam :

1. Azoic color & its application : (Definition, Different names, Properties, Chemistry, Used chemicals in detail, Problems, Stripping, Comparison)

2. Disperse dyes & its application : (Definition, Properties, Dyeing Mechanism, Classification, Application Method, Factors, Used chemicals in detail, Carrier method, HTHP method & Thermasol dyeing method)

3. Technology of Printing : ( Block Printing, Screen printing, Roller printing, Several Comparisons, Direct, Discharge, Resist, Flock, Burnout styles)

4. Technology of finishing : (Mercerization Process, Shearing process, Crease resistant finishing, Water proof & Water repellent finish)

Instructions for Final Exam :

Final Exam Assessment Plan

Time: 2 hours

Marks: 40Final Exam Preparation

- Discuss with each other and find the problems regarding upcoming Final Examination

- If you have any problems that you can not solve, then inform me and we will discuss it in the classroom and here in the Chatbox.